Baldwin-Lomax model

From CFD-Wiki

m |

|||

| Line 1: | Line 1: | ||

| - | The Baldwin-Lomax model is a two-layer algebraic model which gives the eddy-viscosity, <math>\mu_t</math>, as a function of the local boundary layer velocity profile. | + | == Introduction == |

| + | |||

| + | The Baldwin-Lomax model is a two-layer algebraic model which gives the eddy-viscosity, <math>\mu_t</math>, as a function of the local boundary layer velocity profile.The model is suitable for high-speed flows with thin attached boundary-layers, typically present in aerospace and turbomachinery applications. The model is also commonly used in this type of application, especially for quick design iterations where the robustness is more important than getting capturing all details of the flow physics. | ||

| + | |||

| + | == Equations == | ||

<table width="100%"><tr><td> | <table width="100%"><tr><td> | ||

| Line 105: | Line 109: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | |||

| + | == Performance and applicability of the model == | ||

| + | |||

| + | (1). Yes, I think, the state of the art of the turbulence modeling is still not capable of predicting the separated flow accurately. (2). In David Wilcox's book, Section 3.6 Separated Flows, he stated "Menter(1992b) applied the Baldwin-Lomax model to an axisymmetric flow with a strong adverse pressure gradient. The experiment was conducted by Driver(1991). Inspection of the skin friction shows that the Baldwin-Lomax model yields a separation bubble nearly twice as long as the experimentally observed bubble. The corresponding rise in pressure over the separation region is 15% to 20% higher than measured. As pointed out by Menter, the Cebeci-Smith model yields similar results." (3). The question I have is: if an application engineer run the code with Baldwin-Lomax model and obtain the reault with flow separation, then based on the Menter's study, it is not possible for the application engineer to know whether the real flow is separated or not. Menter was very lucky because he is using the experimental data performed by Driver, so he was able to spot the poor performance of the Baldwin-Lomax model. But for the application engineer using the model, I don't think he will ever conduct the experiment to see whether his case is actually separated or not. The experiment to verify the flow separation in turbomachinery is very difficult to perform. (4). At the research level, this is just another opportunity to do research. But for the application engineer, what is going to happen to the results with flow separation? and also the subsequent designs in the real product? (I guess, it's his problem, if he is not reading this forum.) | ||

| + | |||

| + | You are quite right with your comments, as the original Baldwin-Lomax model indeed tends to overpredict separation bubbles. However, there are ad-hoc modifications which reduce this effect. For instance, the predictions of separation are quite sensitive to the Cwk coefficient and higher values than the original ones are known to restrict the early separation. Also, the Granville corrections take partly into account adverse pressure gradient effects, which attenuate the original weaknesses. This to mention that the model can be made to work in an efficient and adequate way for practical applications, without forgetting that, like all algebraic models, it contains less physics than two equation models, which in turn contain less physics than full Reynolds stress models. But particularly for separation predictions, much research is still needed to obtain reliable predictions with any turbulence model. | ||

Revision as of 12:40, 8 September 2005

Contents |

Introduction

The Baldwin-Lomax model is a two-layer algebraic model which gives the eddy-viscosity,  , as a function of the local boundary layer velocity profile.The model is suitable for high-speed flows with thin attached boundary-layers, typically present in aerospace and turbomachinery applications. The model is also commonly used in this type of application, especially for quick design iterations where the robustness is more important than getting capturing all details of the flow physics.

, as a function of the local boundary layer velocity profile.The model is suitable for high-speed flows with thin attached boundary-layers, typically present in aerospace and turbomachinery applications. The model is also commonly used in this type of application, especially for quick design iterations where the robustness is more important than getting capturing all details of the flow physics.

Equations

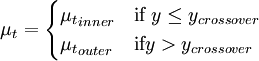

|

| (1) |

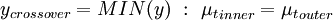

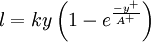

Where  is the smallest distance from the surface where

is the smallest distance from the surface where  is equal to

is equal to  :

:

|

| (2) |

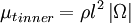

The inner region is given by the Prandtl - Van Driest formula:

|

| (3) |

Where

|

| (4) |

|

| (5) |

|

| (6) |

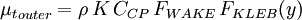

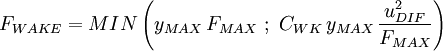

The outer region is given by:

|

| (7) |

Where

|

| (8) |

and

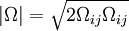

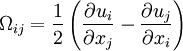

and  are determined from the maximum of the function:

are determined from the maximum of the function:

|

| (9) |

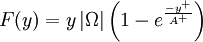

is the intermittency factor given by:

is the intermittency factor given by:

|

| (10) |

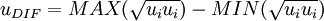

is the difference between maximum and minimum speed in the profile. For boundary layers the minimum is always set to zero.

is the difference between maximum and minimum speed in the profile. For boundary layers the minimum is always set to zero.

|

| (11) |

Model constants

The table below gives the model constants present in the formulas above. Note that  is a constant, and not the turbulence energy, as in other sections. It should also be pointed out that when using the Baldwin-Lomax model the turbulence energy,

is a constant, and not the turbulence energy, as in other sections. It should also be pointed out that when using the Baldwin-Lomax model the turbulence energy,  , present in the governing equations, is set to zero.

, present in the governing equations, is set to zero.

|

|

|

|

|

|

| 26 | 1.6 | 0.3 | 0.25 | 0.4 | 0.0168 |

Performance and applicability of the model

(1). Yes, I think, the state of the art of the turbulence modeling is still not capable of predicting the separated flow accurately. (2). In David Wilcox's book, Section 3.6 Separated Flows, he stated "Menter(1992b) applied the Baldwin-Lomax model to an axisymmetric flow with a strong adverse pressure gradient. The experiment was conducted by Driver(1991). Inspection of the skin friction shows that the Baldwin-Lomax model yields a separation bubble nearly twice as long as the experimentally observed bubble. The corresponding rise in pressure over the separation region is 15% to 20% higher than measured. As pointed out by Menter, the Cebeci-Smith model yields similar results." (3). The question I have is: if an application engineer run the code with Baldwin-Lomax model and obtain the reault with flow separation, then based on the Menter's study, it is not possible for the application engineer to know whether the real flow is separated or not. Menter was very lucky because he is using the experimental data performed by Driver, so he was able to spot the poor performance of the Baldwin-Lomax model. But for the application engineer using the model, I don't think he will ever conduct the experiment to see whether his case is actually separated or not. The experiment to verify the flow separation in turbomachinery is very difficult to perform. (4). At the research level, this is just another opportunity to do research. But for the application engineer, what is going to happen to the results with flow separation? and also the subsequent designs in the real product? (I guess, it's his problem, if he is not reading this forum.)

You are quite right with your comments, as the original Baldwin-Lomax model indeed tends to overpredict separation bubbles. However, there are ad-hoc modifications which reduce this effect. For instance, the predictions of separation are quite sensitive to the Cwk coefficient and higher values than the original ones are known to restrict the early separation. Also, the Granville corrections take partly into account adverse pressure gradient effects, which attenuate the original weaknesses. This to mention that the model can be made to work in an efficient and adequate way for practical applications, without forgetting that, like all algebraic models, it contains less physics than two equation models, which in turn contain less physics than full Reynolds stress models. But particularly for separation predictions, much research is still needed to obtain reliable predictions with any turbulence model.

References

- "Thin Layer Approximation and Algebraic Model for Separated Turbulent Flows" by B. S. Baldwin and H. Lomax, AIAA Paper 78-257, 1978

![F_{KLEB}(y) = \left[1 + 5.5 \left( \frac{y \, C_{KLEB}}{y_{MAX}} \right)^6

\right]^{-1}](/W/images/math/9/b/d/9bde77641b7e232fa3e083d3e59795c4.png)