|

|

|

[Sponsors] | |||||

steady in cylinder simulations: having problems with the mesh and simulation settings |

|

|

|

LinkBack | Thread Tools | Search this Thread | Display Modes |

|

|

|

#1 |

|

New Member

yikai shao

Join Date: Mar 2015

Posts: 15

Rep Power: 11  |

Hello everyone,

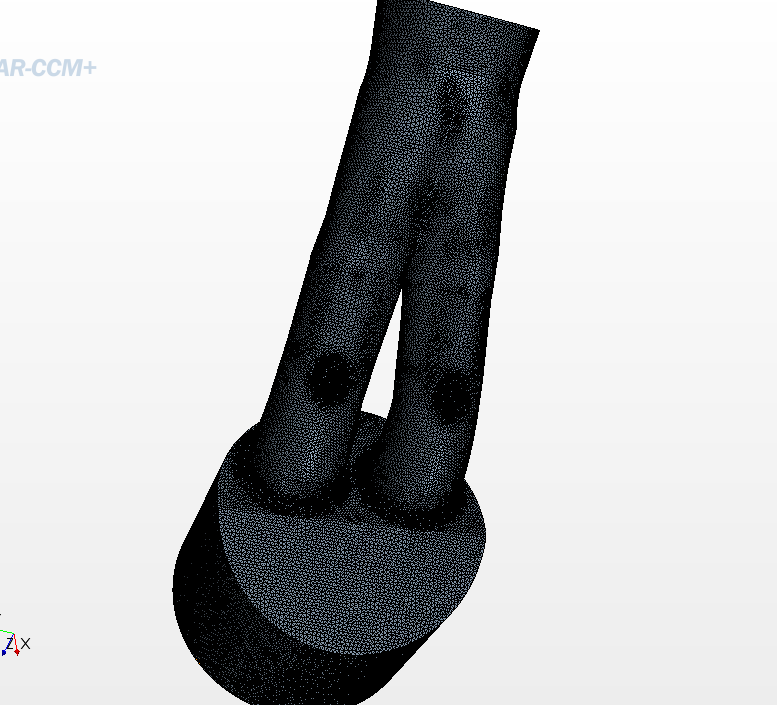

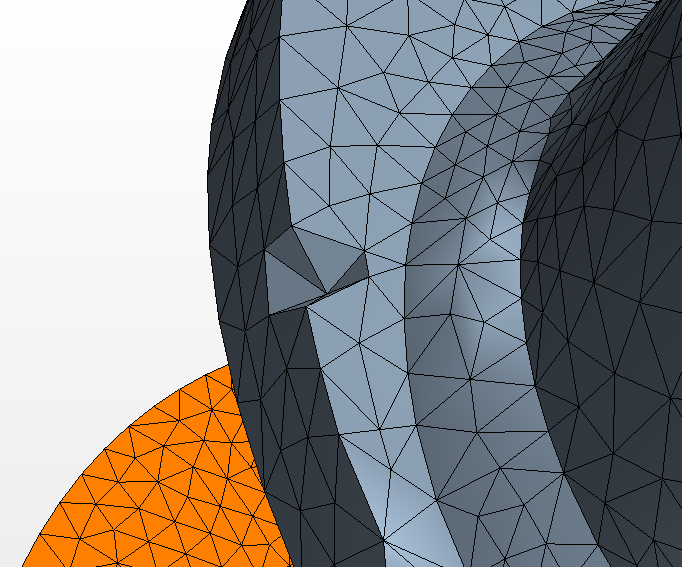

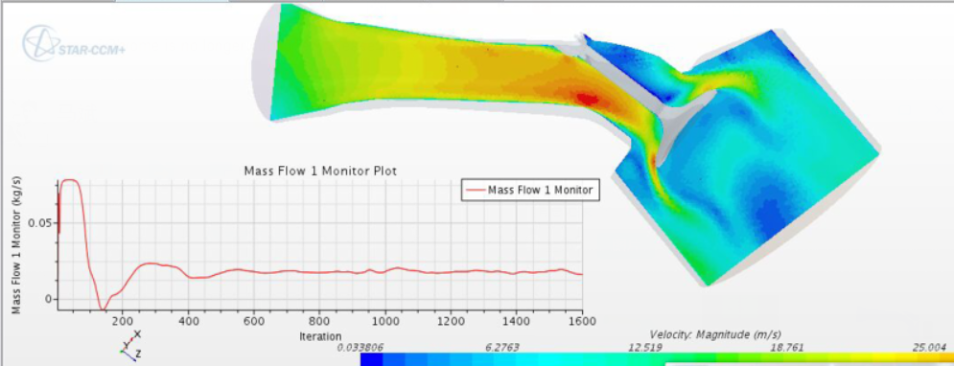

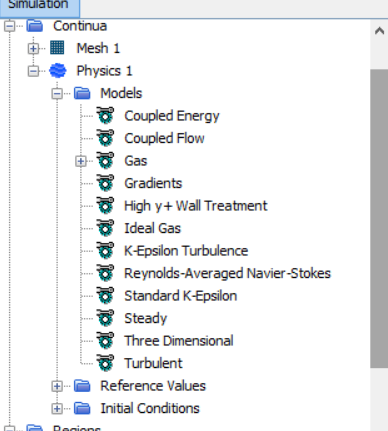

I am doing inlet port design as my uni project with star ccm+. I am having problems now but my supervisor is away.  First of all I am planning to simulat two engine speed, 4500rpm and 14500rpm. There is not a option of velocity outlet. How can I simulate different engine speed? Currently, I am having pressure outlet with negtaive number which makes outlet avg velocity around the piston mean velocity at that engine speed. Is it right way to do? Secondly, I have mesh error when I use corse mesh such as 3mm base mesh. As picture shows below:  It is fine if I use fine mesh like 1mm. It getting worse as base mesh getting bigger. I created the geometry in Solidoworks and input into ccm with STEP file. The last is the simulations are not converging with any of mesh size. The polt of outlet mass flow showing wave.  The model I used:  Thank you in advance.

|

|

|

|

|

|

|

|

|

#2 |

|

New Member

yikai shao

Join Date: Mar 2015

Posts: 15

Rep Power: 11  |

All good now. Solved mesh error with decrease min gap between two parts to 0.5mm. And results became stable as well.

|

|

|

|

|

|

|

|

|

#3 |

|

Senior Member

Matt

Join Date: Aug 2014

Posts: 947

Rep Power: 17  |

FYI, I think you can specify a velocity outlet by giving a negative value. I know this can be done with a mass flow inlet as an outlet, I would assume that it would work for velocity as well.

|

|

|

|

|

|

|

|

|

#4 |

|

New Member

yikai shao

Join Date: Mar 2015

Posts: 15

Rep Power: 11  |

||

|

|

|

|

|

|

|

#5 |

|

New Member

yikai shao

Join Date: Mar 2015

Posts: 15

Rep Power: 11  |

||

|

|

|

|

|

|

|

#6 |

|

Senior Member

Matt

Join Date: Aug 2014

Posts: 947

Rep Power: 17  |

I wouldn't do 2 inlets. You can have one downstream or one upstream. The opposing inlet/outlet should be either a pressure outlet or stagnation inlet. Chances are you will have some convergence issues if you try to use a velocity inlet/outlet arrangement.

|

|

|

|

|

|

|

|

|

#7 |

|

New Member

yikai shao

Join Date: Mar 2015

Posts: 15

Rep Power: 11  |

Im running stagnation inlet and pressure outlet. You think mass flow inlet with preasure outlet will.be.better?

|

|

|

|

|

|

|

|

|

#8 |

|

Senior Member

Matt

Join Date: Aug 2014

Posts: 947

Rep Power: 17  |

that would be my choice, I think.

|

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Issues on the simulation of high-speed compressible flow within turbomachinery | dowlee | OpenFOAM Running, Solving & CFD | 11 | August 6, 2021 06:40 |

| [ICEM] Problems with coedge curves and surfaces | tommymoose | ANSYS Meshing & Geometry | 6 | December 1, 2020 11:12 |

| Problem in initializing transient simulation with a finer mesh | sidd | CFX | 8 | April 29, 2016 02:25 |

| Forces Acting on a Rotating Cylinder (Moving Mesh) | dreamchaser | CFX | 5 | April 25, 2015 06:01 |

| Transient simulation and sliding mesh problems | alige | FLUENT | 0 | May 8, 2006 03:51 |